Circular 530 Clay Dikes

| Geologic Disturbances in Illinois Coal Seams | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Channels | Split Coal | Rolls | Limestone Bosses | Clay Dikes | White Top | Igneous Dikes | Joints | Coal Balls | Miscellaneous Disturbances | Acknowledgments |

Clay Dikes

Clay dikes are intrusions of clay along vertical or inclined fissures in coal seams. They are closely associated with a special type of fault discussed by Krausse et al. (1979a, 1979b) and Nelson (1981). Miners call them confusing' names, such as horsebacks, clay slips, clay veins, and mud slips.

Since clay dikes range from a few inches to several feet wide and a few feet to many hundred feet long, some penetrate the entire height of a coal seam. Others affect only the upper layers of the seam and the lower layers of the roof. Most minable coal beds in Illinois contain these structures, especially the Springfield and Herrin Coals of the western half of Illinois.

Mining problems.

The most detrimental effect of clay dikes is the introduction of waste rock into raw coal. Also, some dikes contain hard, pyrite nodules that accelerate the wear on miner bits. The roof in underground mines is weakened by clay dikes and associated fractures. In Pennsylvania, clay dikes reportedly act either as barriers to or conduits for gas and groundwater within coal seams (McCabe, 1978); such effects have not been observed in Illinois.

Origin

The origin of clay dikes in coal is not yet clear. Probably clay dikes filled from the roof, not from the floor:

- nearly all clay dikes penetrate the roof but few cut through the underclay, and many do not even reach the floor of the seam;

- fragments of roof shale commonly occur in the clay dike within the coal, but fragments of coal are never found in the roof;

- the mineralogy of clay dikes is more similar to roof shales than to underclays (S. Rimmer, personal communication, 1978);

- the drag or folding of coal layers close to the dikes indicates downward rather than upward movement of clay (Savage, 1910).

Therefore, clay dikes formed after layers of sediment had accumulated above the peat, but before the peat and sediments had completely consolidated. If the peat had already hardened into coal, it would have shattered rather than folded and thinned as it ruptured. Yet the materials must have been partly lithified; otherwise fissures would not have stayed open while clay flowed into them. Also, angular fragments of shale and coal inside clay dikes show that sediments were partly hardened when the dikes appeared.

The peat (coal) was stretched apart horizontally. Strata were not shifted up and down much. The offsetting of layers sometimes observed (clay-dike faults) is a local phenomenon accomplished mostly by folding and thickening of some layers rather than others.

Geologists debate the reasons for the stretching. Damberger (1970, 1973) has suggested ground failures during earthquakes, which were subsequently filled with sediments from above. Other geologists favor more gradual processes occurring during compaction and de - watering of peat (Cady, 1915, 1935; Savage, 1910; Wanless, 1952; Wilson, 1916).

Clay Dikes in the Springfield (No. 5) Coal

Of all the minable coal seams in the state, the Springfield Coal of central and northwestern Illinois probably is the most affected by clay dikes. Dikes have been reported in practically every mine in the Springfield district, including Logan, Macon, Menard, and Sangamon Counties, and also in the northwestern district of Fulton, Peoria, Tazewell, and adjacent counties. In contrast, clay dikes are rare in the Springfield Coal of southwestern Illinois and unknown in southeastern Illinois.

The density of clay dikes in the central and northwestern regions, as described in Survey field notes, ranges from "at least one in every room visited" to "only two horsebacks in the mine." In most mines, they were abundant enough to be noted even on brief visits for taking coal samples. It is not unusual to find clay dikes in drill cores in the Springfield district. No quantitative information concerning density and distribution of clay dikes in the Springfield Coal is available because no attempt was made to map the structures systematically. (Survey geologists did note that dikes at a few mines showed preferred orientations.) Distribution of dikes in the Springfield Coal may be controlled by local factors; similar patterns definitely exist for the Herrin Coal, as the following section shows.

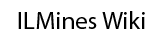

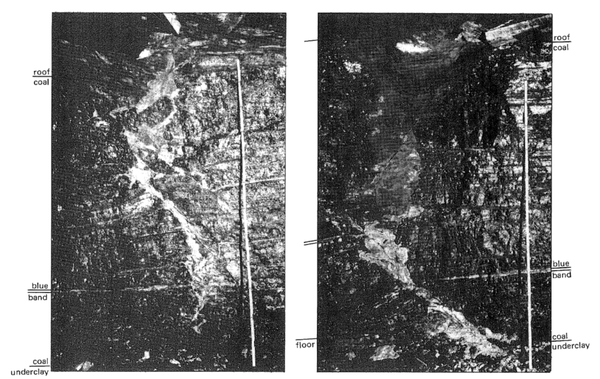

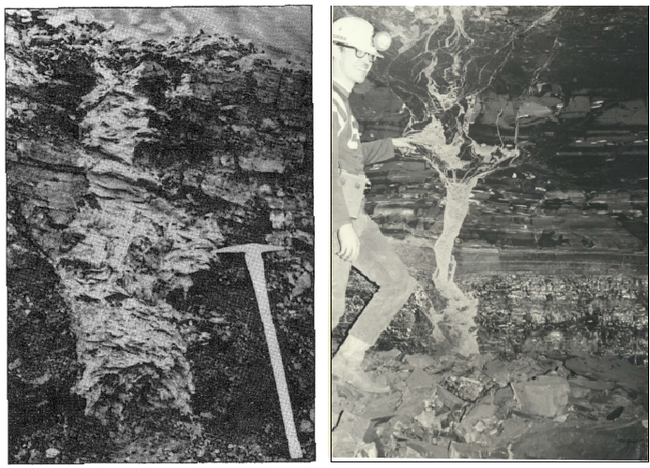

Most clay dikes in the Springfield Coal dip vertically or incline steeply (fig. 31). They may penetrate the entire coal seam or only the upper layers, and they generally extend several feet into the shale above the coal. Although a few cut into the underclay, most end just above the floor; and the underclay bulges beneath the dikes. Hard nodules of pyrite and other minerals are common in these ridges along the floor.

Most dikes described in Survey field notes are a few inches to about 2 feet wide. Occasionally larger ones are reported-up to 15 feet wide in one instance. The intrusions generally are narrower in the roof than in the coal. Also in the roof, dikes have straight, parallel walls; but in the coal, they have highly irregular shapes (fig. 31). Numerous extensions or fingers of clay penetrate the seam laterally. The bedding of the coal is bent, and the seam commonly pinches down slightly next to clay dikes.

The usual filling of dikes is rather soft, light to medium gray clay containing angular fragments of coal and roof shale. Silty or sandy material is found in some dikes. According to observations of Survey geologists, sand-filled dikes were common in several mines in Peoria and Tazewell Counties, where a channel-fill sandstone lies close to or directly above the coal seam. Dikes filled with limestone have rarely been reported. Most clay -filled dikes contain lenses or nodules of pyrite and other sulfides; pyrite also may be concentrated in the coal close to the dikes. All these materials, of course, are unwanted impurities in coal seams.

Mining problems.

Clay dikes are the greatest geologic obstacle to mining in the Springfield Coal of central and northwestern Illinois. Many clay dikes, especial1 y those containing much pyrite, are difficult to excavate during mining. Where underclay bulges beneath the dikes at some mines, the floor had to be leveled (ISGS, unpublished mine notes).

Clay dikes that penetrate the roof severely impair roof stability. Their numerous radiating veinlets of clay (fig. 31) and inclined slickensided fractures allow masses of rock to separate from the roof. The costs of timbering and cleanup after falls were unacceptably high in many of the old mines where clay dikes were abundant. The roof sequence of the Springfield Coal normally does not contain limestone or other competent layers thick enough to support the main roof or provide secure anchorage for roof bolts.

Even where the St. David Limestone is present, it is commonly broken by clay dikes and fractures and falls along with the overlying shale (Damberger, 1973).

Clay Dikes in the Herrin (No. 6) Coal

Clay dikes generally are not the serious hindrances to mining the Herrin Coal as they are to mining the Springfield Coal; however, they are widely distributed in mines from St. Clair County northward to Christian and Sangamon Counties, and in the entire region northwest of the Illinois River. As with the Springfield (No. 5) Coal, dikes are absent or sparse in the southern half of the state.

The size, shape, and filling of dikes are similar in both the Herrin and Springfield Coals. Inclined, rather than vertical, clay dikes are more common in the Herrin Coal than in the Springfield Coal (fig. 32). Moreover, clay-dike faults (Krausse et al., 1979a, 1979b; Nelson, 1981) are much larger and more numerous in the Herrin Coal. The reasons for these structural differences are not known.

In underground mines in the Herrin Coal, detailed mapping of clay dikes shows that their distribution closely correlates with local distribution of rocks in the immediate roof. Krausse et al. (1979a, 19.79b) found that individual dikes tend to remain entirely under one rock type, such as black shale or limestone, and do not cross from areas of shale roof to areas of limestone roof. The dikes and clay-dike faults, moreover, tend to run parallel with the boundaries between different types of rock in the roof. Recent mapping at other mines has confirmed these findings. Knowledge of these relationships may allow limited projection of clay-dike zones ahead of the working face.

Mining problems.

In the Herrin (No. 6) Coal, clay dikes weaken the roof where shale overlies the coal. The effects on roof stability do not appear to be quite as serious as they are in the Springfield Coal because most dikes in the Herrin Coal do not extend very far into the roof. Also, Krausse et al. (1979a, 1979b) found that most larger clay dikes occur where limestone directly overlies the coal. Fractures in the limestone often are "healed" with calcite, so the roof remains stable despite the dikes.

References

- Cady, G. H., 1915, Coal resources of District I (longwall): Illinois Geological Survey Cooperative Coal Mining Investigations Bulletin 10, 149 p.

- Damberger, H. H., 1970, Clastic dikes and related impurities in Herrin (No. 6) and Springfield (No. 5) Coals of the Illinois Basin, in Depositional Environments in Parts of the Carbondale Formation-Western and Northern Illinois: Illinois State Geological Survey Guidebook 8, p. 1 1 1 - 1 19.

- Damberger, H. H., 1973, Physical properties of the Illinois Herrin (No. 6) Coal before burial, as inferred from earthquake induced disturbances: Compte Rendu, Seventh International Congress of Carboniferous Stratigraphy and Geology, v. 2, p. 341 -350.

- Krausse, H.-F., H. H. Damberger, W. J. Nelson, S. R. Hunt, C. T. Ledvina, C. G. Treworgy, and W. A. White, 1979a, Roof strata of the Herrin (No. 6) Coal and associated rock in Illinois-a summary report: lllinois State Geological Survey Mineral Notes 72, 54 p.

- Krausse, H.-F., H. H. Damberger, W. J. Nelson, S. R. Hunt, C. T. Ledvina, C. G. Treworgy, and W. A. White, 1979b, Engineering study of structural geologic features of the Herrin (No. 6) Coal and associated rock in Illinois. Volume 2: lllinois State Geological Survey, Final Contract Report to U.S. Bureau of Mines H0242017, 205 p.

- McCabe, K., 1978, Discontinuities that constitute roof control and other safety hazards: Proceedings, Coal-Seam Discontinuities Symposium, D'Appolonia, Pittsburgh, PA, 18 p.

- Nelson, W. J., 1981, Faults and their effect on coal mining in Illinois: Illinois State Geological Survey Circular 523, 38 p.

- Savage, T. E., 1910, Clay seams or so-called horsebacks near Springfield, Illinois: Economic Geology, v. 5, p. 178- 187.

- Wanless, H. R., 1952, Studies of field relations of coal beds: Nova Scotia Department of Mines, Second Conference on Origin and Constitution of Coal, Crystal Cliffs, Nova Scotia, p. 148- 180.

- Wilson, W. B., 1916, The origin of clay slips: Economic Geology, V. 9, p. 381 -389.