Circular 530 Split Coal

| Geologic Disturbances in Illinois Coal Seams | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Channels | Split Coal | Rolls | Limestone Bosses | Clay Dikes | White Top | Igneous Dikes | Joints | Coal Balls | Miscellaneous Disturbances | Acknowledgments |

Split Coal

Splits are layers of shale, siltstone, sandstone, or other rock within a coal seam. Most seams contain thin partings (usually <I in. thick) of clay or shale, but these are not regarded as splits. No precise definition of split coal exists.

A practical definition includes any coal containing bands of rock that adversely affect the quality and/or rninability of the seam.

Most of the major coal beds in Illinois are split. Some splits are distributed statewide; others are local.

Origin

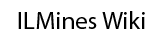

Splits represent interruptions in the coal-forming process. At these times, inorganic materials were deposited in swamps. Certain coal beds in Germany and elsewhere contain layers of volcanic ash (tonsteins); but in Illinois coal seams, ail splits began as sediments deposited by water. Figure 14 illustrates how they developed.

Some splits are infilled channels of small streams that flowed through peat-forming swamps (fig. 14a); they can be recognized by their lenticular cross sections and linear or meandering outlines in map view. Along the margins of these splits, coal usually interfingers with the channel-fill deposits.

Other splits consist of sediments deposited in small lakes or ponds within the swamps (fig. 14b). Today, areas such as the present Mississippi delta contain hundreds of small, short-lived lakes that fill with mud and silt from floodwaters. If peat growth is re-established on these deposits, a split seam will eventually result. Also, splits that form in lakes or ponds are lenticular in cross section, but have rounded or irregular outlines rather than the sinuous, linear patterns of stream deposits. Lake-bed deposits commonly consist of dark, very fine-grained shale with thin parallel laminations. Occasionally, cannel coal is associated with lake-bed deposits. Composed mainly of windblown spores and pollen from trees surrounding the water, cannel coal is dull, hard, and nonbanded with a waxy or greasy lustre. Usually, it is higher in ash than banded coal.

Most splits in Illinois probably began as overbank deposits-sediments washed out of rivers and streams into the swamps during floods (fig. 14c). After the floodwaters receded, peat developed again on the sediments. In some places, this process was repeated many times, yielding coal beds with multiple splits. Overbank-derived splits may cover many square miles. Although such deposits are usually thin (a few inches to a few feet at most), some gradually thicken toward their channels. Fine-grained rocks such as mudstone, shale, or siltstone make up most of these splits.

Closely related to the overbank deposit is the crevasse splay. When a river cut a large gap or crevasse through its natural levees (figs. 8 and 14), the diverted flow spread across the lowlands. Immediately a fan- or lobe-shaped deposit began to build up: a crevasse splay is, in fact, a small delta. (Today, crevasse splays are forming in deltas around the world, including the Mississippi delta). Sediments were thickest and coarsest next to the crevasse, and gradually became thin and fine grained toward the outer edges. A split formed when a splay deposit, which had been building on top of a peat deposit, was abandoned. Then new peat grew on top of the splay. The Energy Shale and the Dykersburg Shale appear, in part, to be crevasse splays deposited by the Walshville and Galatia streams near the end of peat-forming periods.

Still another way of forming splits (not illustrated) was through a short-term rise in sea level. Swamps flooded with salt water, killed plants, and halted accumulation of peat. Thin marine sediments, such as black shale or limestone, settled on top of the peat. When the sea withdrew, a new peat swamp developed on top of the marine deposits. Geologists regard the two beds thus formed as separate coals. If the split is thin enough, however, the two seams can be mined together. In Illinois, minable coal split by marine rocks has not been documented.

Mining Conditions

Splits in a coal seam always hamper production, so mine operators generally have avoided them. Illinois contains large reserves of coal without splits, but as these deposits are mined out, attention will focus on mining split coal. Much of it is thick and low in sulfur.

Thin splits can be mined with the coal. If the coal is not cleaned, the ash content of the product is raised. In fact, the increase in ash is greater than one might expect because most split material is about twice as dense as coal. If shale in a seam amounts to 1 percent by volume, it contributes 2 percent ash by weight. Each inch of shale mined with a 6-foot seam adds roughly 2.5 percent to the ash content of the raw coal.

A preparation plant can remove some split material. Plants are designed to operate most efficiently within a certain range of percentage of waste in the raw coal. If this range is exceeded due to mining of severely split coal, the cleaning plant may not be able to handle the excess rock. The result will be either a dramatic increase in ash in the shipped coal, or large amounts of coal sent to the waste pile (increasing the hazard of fire). Furthermore, increased wear on crushers, screens, and other equipment will occur when large amounts of rock are sent to the preparation plant.

Another way to handle splits is to mine the coal in benches, separating the rock during mining. Disposing of waste rock is no problem in surface mining; it can be placed in the spoils with the overburden. Removing the split, however, raises the cost of mining. Special equipment may be necessary, as most loading machines are not well suited to removing thin layers of rock cleanly from the seam.

The difficulties of working separate benches are magnified in underground mining. Achieving clean separation of coal from split material is difficult or impossible with modern face equipment, especially with continuous miners. As in strip mining, the extra operation of removing the split increases mining costs. If the splits are thick, the height of entries may become excessive, with increased danger of roof and rib failure. Finally, disposal of waste rock is a problem. It can be stored in the mine as gob, but space for such storage is limited, and spontaneous combustion of gob is a serious problem. If the rock is sent out of the mine, it goes through the preparation plant; then the company must find a place on the surface for the waste.

It is also possible to mine only one bench of the split coal, leaving the split and other bench(es) in the ground. The resultant loss of reserves makes this practice unattractive, unless the split lies close to the bottom or top of the seam. Thick splits near the middle of the seam present an unhappy choice, especially in underground mining where maintaining a minimum working height is critical. Unless the extent of the split is known to be limited with good coal beyond it, mining may be halted.

When a choice exists between mining an upper or a lower bench of split coal in a deep mine, the character and stability of the roof and floor are considered. If the lower bench is extracted, the split becomes the roof. Many splits are composed of weak shale or claystone, prone to slaking and generally weak. They may be weakened further by coaly stringers and partings as well as rooted zones (underclays) beneath the upper bench of coal. The roof also may split along bedding planes in the upper, unmined bench of coal. Another problem is that the lower bench frequently dips; mining it leaves depressions that accumulate water. In such a case, mining the upper bench would be preferable. In other cases, where the split consists of competent rock, and groundwater is no problem, mining the lower bench of a split seam should cause little trouble.

Some splits, persisting over hundreds of thousands of acres and varying little in thickness, can be mapped accurately from exploratory drill holes. Most overbank deposits and crevasse splays fall into this category. Other splits, especially those from stream deposits, are localized. Since they vary from site to site, where they will appear ahead of the working face is almost impossible to predict. Mining plans can accommodate only uniform and continuous splits.

Splits in the Murphysboro Coal

The Murphysboro Coal of southern Illinois (formerly, but incorrectly, called the "No. 2 Coal") is mostly split where it is thick enough to mine. Typically the coal divides into an upper bench 1 '/2 to 3% feet thick and a lower bench 3% to 4% feet thick. One shale bed persisted through nearly all, the underground mines formerly worked around Murphysboro. The shale was medium to dark gray, fine grained, and often abundantly carbonaceous, containing stringers of coal; its thickness varied from less than I inch to as much as 36 feet (Andros, 1914; Jacobson, 1983). Toward the Oraville channel, the split thickened gradually, representing overbank or crevasse -splay deposits associated with the channel (Treworgy and Jacobson, 1979).

In addition to the main split, other shale layers were encountered in several mines. In the southern workings of Consolidated Coal Company Mine No. 10, the lower bench of coal was split 12 inches below the top. Elsewhere, localized lenses of shale and siltstone occurred in the Murphysboro Coal, possible small streams or lake deposits in the coal -forming swamp.

Mining problems.

Both benches of coal were mined where the split(s) were thin. Where the shale was more than a few feet thick, the lower bench was exploited and the upper bench left in the roof. Only the lowermost 44 inches of the coal was taken in the southern part of Consolidation No. 10. Many mines reported difficulty in supporting the split as roof. Carbonaceous partings and coaly stringers weakened it, and exposure to moisture in the air softened it. The dark shales were said to be more susceptible to slaking than the light shales (Andros, 1914).

Split in the Seelyville Coal

The Seelyville (Indiana III) Coal appears to be split through much of east-central Illinois. Electric logs of numerous oil -test holes and the few coal-test borings available indicate a layer of shale or siltstone ranging from 1 to more than 5 feet thick, generally near the middle of the seam. This split is one of several factors that have deterred companies from mining the Seelyville Coal, despite its great extent and often considerable thickness (Treworgy, 1981).

The Davis and De Koven Coals may represent the lower and upper benches, respectively, of the Seelyville Coal (Treworgy, 1981). In southeastern Illinois and western Kentucky the Davis and De Koven Coals have been mined extensively, mostly by stripping. The two seams are separated by as much as 50 feet (commonly 20 to 30 feet) of shale, siltstone, and sandstone. The interval gradually thins northward, and the two seams take on the appearance of a single coal with a split.

Splits in the Springfield (No. 5) Coal

The Springfield Coal is split in many places along the Galatia channel (fig. 10). The coal affected includes the thickest Springfield Coal in Illinois, and much is low in sulfur. The splits vary in their number, thickness, composition, extent, and position in the seam. They appear to be largely overbank deposits from the Galatia channel, but some probably formed in lakes, streams, and other environments.

Some splits, apparently overbank deposits, extend over several square miles. In the southeastern workings of Peabody Mine No, 47 (Harco Mine) in Section 35, 5. 8 S., R. 5 E., Saline County, a wedge of shale appeared about 30 inches above the base of the coal; it reached a thickness of several feet and necessitated leaving the lower bench in the floor. At the Galatia Coal Company mine in Section 11, T. 8 S., R. 5 E., Saline County, the lower 0.3 to 3.0 feet of the 6-foot seam consisted of bony coal thinly interbedded with clay and streaks of bright coal. The thickness of this zone increased toward the Galatia channel; additional shale bands appeared in the coal close to the edge of the channel.

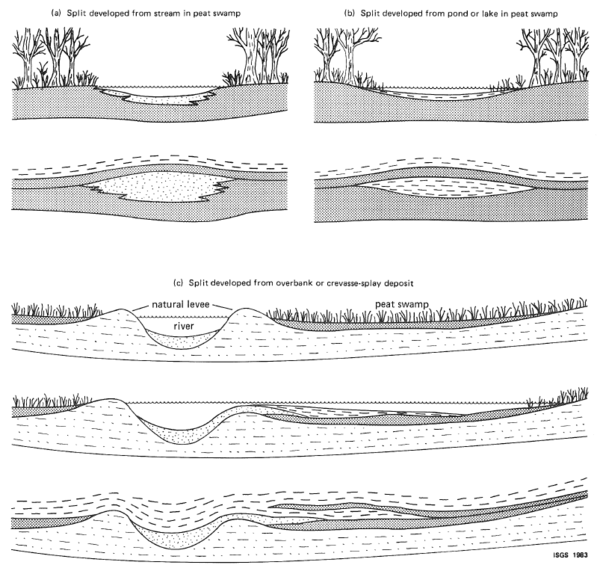

Farther southward, splits occur in the upper rather than the lower part of the coal. The area most severely affected includes the northeastern part of the Sahara Coal Company Mine No. I6 (abandoned) and the southeastern portion of Sahara Mine No. 20 (active) in Sections I 1 and 12, T. 9 S., R. 5 E., Saline County. In both mines approximately 6 feet of clean, low-sulfur coal is overlain by as much as 12 feet of thinly laminated coal, bone, and carbonaceous shale (fig. 15). Mud-laden floodwaters must have invaded the coal swamp repeatedly to produce such a deposit.

The same mines contain localized splits apparently deposited in streams flowing through the coal swamp. Splits mapped in the southern workings of Sahara No. 16 (Sec. 19, T. 9 S., R. 5 E.) follow curving, sinuous, or branched courses for thousands of feet. The splits are lens shaped in cross section; some are 20 feet or more thick and several hundred feet across. In Sahara No. 20 (Sec. 2, T. 9 S., R. 5 E.) the coal is abruptly divided by a thick lens of siltstone, located about one-third the distance above the seam floor. The lower bench of coal, which was not mined, pitches sharply downward beneath the lens; the upper bench rises sharply over the siltstone, thinning and splitting further. The split thickens from 0 to 10 feet in about 100 feet. It is several hundred feet across and has blunt, rounded ends. The areal extent is not known because only one set of entries encountered the split.

The large, roughly oval area of split coal left unmined at the Eldorado Corporation Dering Mine No. 2 (Sec. 13, T. 8 S., R. 6 E., and Sec. 18, T. 8 S., R. 7 E.) probably formed in a lake within the coal swamp. Field notes taken by Survey geologists who visited the now-abandoned mine indicate that the split was composed of silty shale and siltstone, dividing the coal into two benches. In cross section, the split resembled a thick lens with abrupt margins. Whether both benches of coal were continuous across the lens is not known. Some holes drilled within the unmined area show unsplit coal of normal thickness, perhaps the result of islands in the lake.

A large area of thin coal (< 4 ft), locally split, has been mapped from drill-hole data in T. 8 S., R. 6 E. and east-central T. 8 S., R. 5 E., Saline County (fig. 11). The irregular pattern of mining on the northwest side of Sahara Coal Company Mine No. 1 testifies to repeated probes of the thin coal. The Springfield Coal appears to thin gradually from i t s normal 6 to 7 feet to as little as a few inches; but at least one island of thick coal is present. An unusually thick deposit of Dykersburg Shale, a crevasse splay from the Galatia channel, overlies this thin coal. In fact, the lobate outline of the area suggests a crevasse splay. Perhaps the Galatia river broke through its east bank during the later stages of peat formation, washed out some of the peat, and deposited the thick wedge of Dykersburg Shale above the eroded peat.

Along the Galatia channel north of Saline County, drilling and mining have revealed additional areas of split coal. Divided coal has been identified in Wabash, White, and Hamilton Counties, and encountered in mines farther eastward in Indiana along the Galatia channel and its tributaries.

Mining problems.

Splits in the Springfield (No. 5) Coal reduce recoverable reserves, increase mining costs, and hamper roof control. At the Galatia Coal Company and Peabody Coal Company Harco Mine, the shaly partings and lower coal benches had to be left in the floor. Sahara Coal Company eventually retreated from the area of thick, interlaminated shale and coal because of extreme difficulty supporting the roof (Walter Lucas, Sahara Coal Company, personal communications, 1977). In the areas of channel-like splits, Sahara mined only the upper bench of coal. Eldorado Corporation did not attempt to mine coal under the lake deposits; but the company was forced to drive ventilation entries through the siltstone, thus allowing geologists to view its internal structure.

Splits in the Herrin (No. 6) Coal

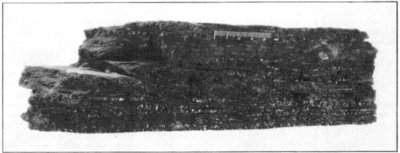

The famous "blue band" of the Herrin (No. 6) Coal (fig. 16) is distributed throughout the Illinois Basin Coal Field. It is a layer of shale or hard clay, normally 1 to 3 inches thick, occurring in the lower half of the seam. Although the position of the "blue band" varies from just a few inches above the floor to about midseam, it usually lies about one-fourth to one-third the distance from bottom to top of the seam.

Over much of Fulton, Knox, Peoria, and Stark Counties, and some of Macoupin and neighboring counties, the Herrin Coal contains additional partings. The most widespread is sometimes called the "steel band" and occurs above the "blue band" near or slightly above the middle of the coal. At some mines two bands of shale or clay occur above the "blue band." Elsewhere the "blue" and "steel" bands both appear along with a third split below the "blue band" (Wanless, 1957). Although these splits commonly appear to be continuous throughout a mine, they are difficult to correlate over large areas.

Also, a thin parting of dark gray to black pyritic shale lies 6 to 12 inches from the top of the Herrin Coal in Gallatin and Saline Counties as well as in adjacent western Kentucky.

The origin of the "blue band" and its relatives puzzles geologists. Some have suggested volcanic ash (tonsteins), although the proper minerals and microscopic structure are lacking. Possibly the bands are overbank deposits; yet this theory, which is supported by local thickening of the "blue band" near the Walshville channel, calls for basinwide floods that left only 1 or 2 inches of mud as a record. Topographic variations in the peat swamp, though slight, should have produced a flood deposit more discontinuous and irregular in thickness than the "blue band." Some geologists question whether the "blue band" is actually the same parting throughout the Illinois Basin.

Mining problems.

Although the "blue band" and related partings cause few problems in mining, they add to the proportion of ash in raw coal; however, most shale can be removed in the preparation plant. In some underground mines the "blue band" lies close to the floor. Both the band and the underlying coal may be left in place, probably as much to provide a solid floor as to avoid mining the shale. At many modern mines the "blue band" provides a guide for continuous-miner operators to judge their position in the seam and avoid mining into the underclay.

Split coal along the Walshville channel

Nearly all splits that seriously interfere with mining the Herrin (No. 6) Coal are found near the Walshville channel. These splits are overbank deposits, crevasse splays, and related sediments from the channel, which was active as the Herrin peat was forming.

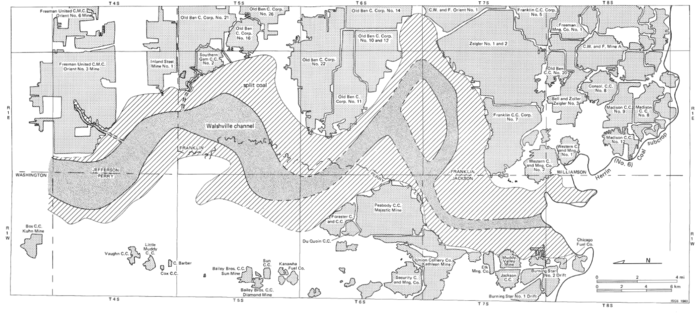

The relationship of split coal to the Walshville channel is shown in map view on figure 5. Clearly, split areas vary greatly in width and extent. In eastern Macoupin County, splits are found as far as 4 miles from the channel. Other long stretches of the channel seem to have no flanking split coal. Interpret the map with caution, however, as large segments of the channel are charted from widely scattered oil-test holes. Identification of split coal on electric logs must be confirmed by coal-test cores or exposures in mines. Although figure 5 shows no split coal in many areas, where enough data are available, split coal is almost always found along the channel. This includes the "Quality Circle" - named for its thick, low-sulfur deposits. The coal is continuously split along both banks of the Walshville channel in the "Quality Circle," which includes parts of Jefferson, Franklin, Perry, Jackson, and Williamson Counties in southern Illinois (fig. 17). The boundary of split coal in figure 17 is only approximate. In coal-test cores, coal containing 3 inches or more of shale was mapped as split; but recognizing splits thinner than 1 foot is difficult on electric logs of oil-test holes.

Some splits near the Walshville channel cover large areas, change gradually in thickness, and appear to be overbank deposits-thin clay partings in the coal that increase to several feet thick near the channel. At Inland Steel Mine No. 1 in Jefferson County, a thin parting 1.8 feet below the top of the seam thickens westward toward the channel, becoming nearly 1 foot thick 1000 feet away. Other westward -thickening splits were observed below the main split. Similar thick, uniform, shale splits occur in the upper part of the Herrin Coal in the westernmost workings of the abandoned Old Ben Mine No. 11 (fig. 18).

The "blue band" becomes unusually thick in some places. East of the Walshville channel the "blue band" thickens to nearly 2 feet over more than 1000 feet in Old Ben Mine No. 21. E. T. Benson (ISGS, unpublished mine notes, 1933) reported the "blue band" reached 14 inches thick in the Southern Gem Mine No. 2, southern Franklin County. West of the channel, the "blue band" thickened to 10 inches at the Muddy Valley Mine (K. D. White, unpublished field notes) and at the Chicago Fuel Company Mine (Cady and Savage, unpublished field notes), both in eastern Jackson County. These findings support the idea that the "blue band" is an overbank deposit.

Changes in coal quality may accompany splitting. Kravits and Crelling (1981) report that the ash content of the Herrin Coal at the Burning Star Mine No. 5 Jackson County increases near the Walshville channel. The coal at Burning Star Mine No. 5 is divided into three benches by two shale or claystone splits that vary from 1 to 10 inches thick. (These shale bands were excluded from the samples sent for analysis.) The ash in both the upper and the middle bench (the lower bench was not sampled) increases to more than 20 percent close to the channel, which lies immediately west of the mine. The increased ash probably reflects larger quantities of mud intermixed with the peat near the channel. Kravits and Crelling (1981) also found petrographic changes in the coal, suggesting the peat near the channel was partially decayed, or oxidized, before coalification.

Mining problems.

The irregular borders of mines along the split-coal area (fig. 17) reflect differing policies of coal companies on mining split coal. Some operators abandoned the effort when splits became more than a few inches thick. Others probed deeply into split coal, perhaps taking only one bench of the seam.

An interesting example is the Clarkson Mine at Nashville in Washington County, which lay inside a horseshoe loop of the Walshville channel. Throughout the mine, the seam averaged 9 feet thick, although the lower 3 to 4 feet of bone coal (finely interbedded coal and black carbonaceous shale) was usually left in the floor. The "blue band" was 2 to 5 inches thick; about 3 inches above it was another shale band 2 to 3 inches thick. The miners referred to the bands together as the "buck band" and discarded them during mining. Sometimes the coal was mined in two benches, cutting out the "buck band" by machine. At other times, the whole seam was shot down at once, and the shale was picked out by hand. Either way it was extra work.

The case of the Clarkson Mine also shows that split coal is not always overlain by gray shale (Cady et al., 1945); the roof in most of the mine was black shale or limestone, although gray Energy Shale was present in some places.

Case Studies in the Herrin (No. 6) Coal

Two small offshoots of the Walshville channel show in the northeastern part of figure 17. One penetrates the workings of the Freeman United Orient Mine No. 3, and the other enters Old Ben Mine No. 21. The channels and their associated split coal and rolls severely disrupt mining operations. The following two case studies illustrate the complexity and variety of splitting phenomena along the Walshville channel as well as some ways coal companies have mined disturbed coal.

The disturbed belt at the Orient Mine No. 3

A broad belt of severely split, thinned, and locally eroded coal cuts through the Orient No. 3 Mine of Freeman United Coal Mining Company in southwestern Jefferson County. The disturbed belt is a t least '12,060 feet long, averages 1,000 feet wide, and trends northeast at a right angle to the Walshville channel, which is southwest of the mine. The shape, position, and structure of the disturbed belt indicate it is either a tributary or a distributary of the main Walshville channel (fig. 17). The margins of the disturbance are sharp. Miners come upon them without warning. Some faces butt abruptly into solid rock or run into severely split coal. The seam suddenly pitches up or down, or pinches out. Surveyors' sketches show no consistency in shape, thickness, or position of splits. Away from the belt the coal is generally level and normally thick with no unusual shale bands or other disturbances.

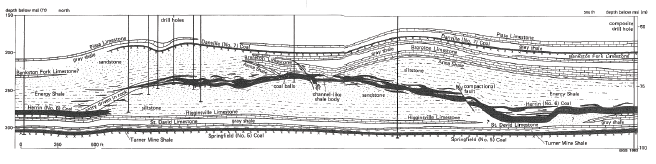

One pair of entries known as the Return Air Courses (WAC) had to be driven through the disturbed belt to ventilate part of the mine. Before mining the RAC, Freeman drilled test holes to plan their attack. Nevertheless, driving the RAC was slow, laborious, and costly.

Figure 19, a geologic cross section of the RAC, shows how the coal terminated abruptly against siltstone on the north side of the disturbed belt. Drilling ahead of the face showed the coal reappearing southward, approximately 35 feet higher. Accordingly, the miners graded back to the north and then angled the headings into the roof. This northern uphill stretch was the only significant part of the RAC that had to be mined entirely in rock: exposed here was a gray, hard, faintly laminated siltstone containing numerous lenses and curving stringers of coal that probably originated as mats of peat ripped up by currents and mixed with silt.

A few hundred feet southward, the RAC entered an area of thicker coal interbedded with siltstone, silty shale, and fine-grained sandstone. (The same materials also overlie and underlie the coal; the underclay was either very thin or missing.) The benches of coal thickened and tended to come together southward. The seam rose and fell like a roller coaster, then gradually rose toward the midpoint of the RAC, where it reached its highest elevation.

Continuing southward, the Herrin Coal began to drop. Unexpectedly, in the central area the seam was overlain not by siltstone-but by black fissile Anna Shale and marine Brereton Limestone (fig. 19). Drilling away from the disturbed belt showed that the Anna and Brereton ordinarily overlie at least 30 feet of gray Energy Shale or siltstone above the coal. In this small area of black shale/limestone roof the Herrin Coal contained unusual and highly interesting features, including large masses of coal balls, some highly peculiar faults displacing the coal, and a thick, linear, channel-like body of soft gray shale within the seam.

Also, as the seam dropped in elevation, it again became severely split by layers of shale and siltstone up to 5 feet thick. The coal was offset by several large, curving faults that probably were caused by unequal compaction of peat around lenticular bodies of mud and silt. One fault displaced the coal I0 feet downward in one entry but only 4 feet in the other entry about 50 feet away. These faults, along with the splitting and steep dip of the coal bed, made it difficult for miners to keep the headings within the coal. The same conditions also hampered roof control, both during and after mining.

In the area where the RAC rejoined normal mine workings south of the disturbed belt, the main bench of the seam dropped into a deep trough or basin. The main bench was about 8 feet thick and overlain by about 12 feet of medium to dark gray shale, above which was another 2- to 5-foot coal bed. The shale between these two thick benches also contained thinner layers of coal. Ail layers were horizontal in the bottom of the trough or basin. On the south side of the depressed area, the 8-foot bench rose about 12 feet at a 20-degree angle, then abruptly leveled out. Here the upper benches of coal apparently pinched out in the roof. South of this point, the Herrin Coal was level to slightly hilly and uniformly thick, with only minor splitting near the top of the seam. This coal was mined in a normal pattern.

In the profile of the RAC (fig. 19), the Herrin Coal forms a broad arch, broken on the north side. Drilling indicated (1) a similar pattern all along the disturbed belt, and (2) the Higginsville Limestone and deeper strata, including the St. David Limestone and the Springfield Coal, lying horizontally and nearly continuously beneath the disturbed belt. The arch in the Herrin Coal was caused by siltstone and sandstone, as much as 50 feet thick, between the coal and the top of the Higginsville Limestone. This thick body of rock fills an interval normally held by only 2 or 3 feet of underclay.

We can visualize a stream flowing in this area shortly before the Herrin peat began to form. The channel bed was filled with silt, sand, and mud. Then either a temporary reduction in flow or a slight shift in the channel's course allowed peat to develop on top of the channel fill. Water continued to flow through the area, washing out large masses of peat and depositing sediments, which later became splits in the seam. Then floodwaters overflowing or breaking gaps in the banks of the main Walshville channel placed mud and silt (Energy Shale) on top of the peat. In most places, the peat settled and compacted. Over the buried channel, it formed an arch.

There are several questions about the disturbed belt in Orient No. 3, including whether this small channel flowed into or away from the main Walshville channel, and why the disturbed belt abruptly ends on the northeast within the mine workings. We would expect a river up to 1/4 mile wide and 50 feet deep to extend more than 2% miles. Perhaps it does continue, but is completely concealed above or below the Herrin Coal. One thing is certain-the disturbed belt at Orient No. 3 is one of the most fascinating and complicated geologic features affecting coal mining in Illinois.

Split coal and channels at Old Ben Mine No. 21

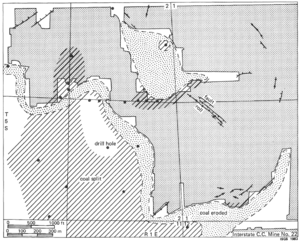

The northwestern workings of Old Ben Mine No. 21 in Franklin County (T. 5 S., R. 1 E.) were plagued by various disturbances, including eroded areas and severely split coal. These disturbances, like those at Orient No. 3, appear to be related to small channels that branched away from the main Walshville channel west of the present mine (fig. 17).

Figure 20 shows features encountered in the mine as well as in test drilling. Along the western and southern margins of the mined-out area, coal was eroded along a narrow, meandering belt-probably a stream channel-and replaced by siltstone and fine-grained sandstone layered with conglomerate and stringers of rafted coal. The edges of the cutout dip as steeply as 30 degrees in places, and the coal pitches downward as its upper layers are truncated.

Drilling indicates split coal in most of the region south and west of the narrow channel, although two drill holes (fig. 20) penetrated coal of near-normal thickness with no significant shale bands. The mine operators left this coal because they judged its value to be less than the expense of mining through the channel. Northeast of the channel, coal was mined despite the splits consisting of medium to dark gray shale up to several inches thick, mostly located in the lower half of the seam. One shale layer appeared to be the "blue band," although it was thicker than normal. Close to the edges of the cutout the coal became more severely split. According to one interpretation, these thick wedges of siltstone in the coal near channel margins were originally silty sediments injected from the stream into soft peat (M. E. Hopkins and Fred Murray, unpublished field notes, 1966).

A second area where the coal has been eroded lies mostly in the northeast quarter of Section 2, T. 5 S., R. 'I E. (fig. 20). The borders were probed during mining, and one drill hole penetrated split coal. The roughly oval outline of the erosion suggests it represents a lake deposit rather than a stream channel. In fact, the absence of coal may be due not only to erosion, but also to nondeposition of peat within the lake.

References

- · Andros, S. D., 1914, Coal mining practice in District VII: lllinois State Geological Survey Cooperative Coal Mining Investigations Bulletin 4, 53 p.

- · Kravits, C. M., and J. C. Crelling, 1981, Effects of overbank deposition on the quality and maceral composition of the Herrin (No. 6) Coal (Pennsylvanian) of southern Illinois: International Journal of Coal Geology, v. 1, p. 195-212.

- · Treworgy, C. G., 1981, The Seelyville Coal-a major unexploited seam in Illinois: lllinois State Geological Survey Mineral Notes 80, 11 p.

- · Treworgy, C. G., and R. J. Jacobson, 1979, Paleoenvironments and distribution of low-sulfur coal in Illinois: Abstract, Ninth International Congress of Carboniferous Geology and Stratigraphy.

- · Wanless, H. R., 1957, Geology and mineral resources of the Beardstown, Glasford, Havana, and Vermont Quadrangles: Illinois State Geological Survey Bulletin 82, 233 p.